Polycarbonate Solid Sheets

Unveiling the Power of Solid Polycarbonate Sheets

The Clear Alternative to Glass

In the world of construction and manufacturing, few materials have challenged the dominance of traditional glass quite like Polycarbonate Solid Sheets. These transparent thermoplastic panels are not merely a substitute; they represent a significant upgrade in terms of safety, durability, and performance across countless applications.

Known commercially by trade names like Lexan or Makrolon, a solid polycarbonate sheet is a dense, homogeneous plastic panel that mimics the clarity of glass while offering a host of superior mechanical properties.

Projects

The Core Strength: Unmatched Impact Resistance

The single greatest feature that defines solid polycarbonate sheets is their virtually unbreakable nature. This characteristic stems from the material's unique molecular structure, making it the ideal choice where security and safety are paramount.

- 250x Stronger than Glass: Polycarbonate solid sheets can withstand enormous force, often being cited as 250 times more impact-resistant than standard glass and up to 30 times stronger than acrylic sheeting.

- Shatterproof Security: Unlike glass, which shatters into dangerous fragments upon impact, polycarbonate will crack or deform but will not break apart. This makes it the material of choice for high-security, anti-vandal, and protective glazing applications.

- Extreme Weather Resilience: It stands up effortlessly to high winds, heavy snow loads, and severe hail without risk of breakage.

Key Features and Performance Benefits

Beyond its toughness, solid polycarbonate offers a suite of features that drive its adoption in diverse industries:

| Feature | Performance Benefit | Application Highlight |

| Optical Clarity | High light transmission (up to 90%), comparable to glass, ensuring brilliant, clear views. | Windows, Skylights, Machine Guards |

| Lightweight | Roughly half the weight of glass of the same thickness, significantly easing installation and reducing structural load. | Roofing, Vehicle Windows (e.g., race cars) |

| UV Protection | Co-extruded UV-resistant layers prevent the sheet from yellowing and degrading over time, ensuring a long service life outdoors. | Outdoor Signage, Glazing, Canopies |

| Thermal Stability | Maintains its physical properties across an extremely wide temperature range (e.g., $-40^\circ\text{C}$ to $120^\circ\text{C}$), preventing deformation. | Industrial Components, High-Heat Lighting Fixtures |

| Fire Safety | Inherently flame-retardant and self-extinguishing when the ignition source is removed, often achieving a high fire rating. | Public Transport, Building Cladding |

| Formability | Can be easily cut, drilled, and bent (cold-formed) or thermoformed into complex, custom shapes without pre-heating. | Architectural Domes, Curved Facades |

Where Solid Sheets Shine: Common Applications

The combination of clarity and strength makes solid polycarbonate the default choice for specific high-performance roles:

- Safety and Security Glazing: Used in environments where breakage is a risk or concern, including school windows, bank teller windows, prison glazing, police riot shields, and armoured vehicle windows.

- Architectural Features: For high-end, clear roofing where maximum light transmission and durability are required, such as commercial skylights, large dome structures, and barrel vaults.

- Industrial Protection: Transparent machine guards, protective screens, safety barriers, and instrument panels that must withstand impact while maintaining visibility.

- Signage and Displays: Durable faces for illuminated signs, billboards, and point-of-sale displays that are exposed to public interaction and weather.

- Transportation: Headlight lenses, bus shelter walls, and lightweight windows for planes and trains.

Solid vs. Hollow: The Key Differentiator

While the hollow (multiwall) variant of polycarbonate is preferred for its superior thermal insulation (thanks to the air pockets), the solid variant is chosen for its:

- Maximum Impact Resistance: The dense, non-fluted structure provides the ultimate barrier against direct, focused force.

- Optical Perfection: The single-layer panel offers the best possible clarity and an unobstructed view, matching that of glass.

In essence, if the project priority is security and crystal-clear vision

ADVANTAGE

- High fire rating - Self extinguishing

- Impact resistant and durable

- High light transmission

- Water-Clear Clarity

- Excellent chemical resistance

- Optional UV resistance coating on one side

- Optional high-impact to limit fragility

- Easily thermoformed and fabricated

- Optional anti-glare finish on one side to eliminate

- Disturbing glare

APPLICATION

- LIGHTING

- SHOP SHOW COVER

- ROOFING

- ADVERTISING PANEL

- SIGNAGE

- SOUNDBARRIER

- BATHROOM

- CANOPY/CARPORT

- SKYLIGHT

- WALK WAYS

Related Pages

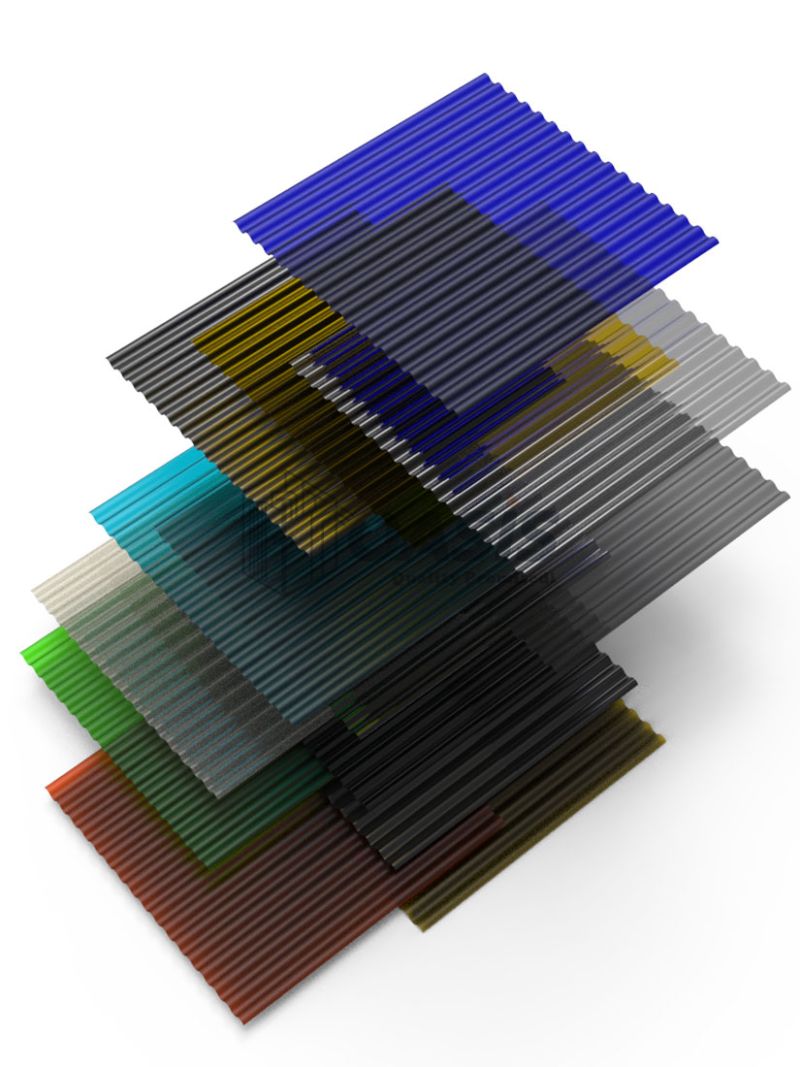

polycarbonate corrugated sheet, polycarbonate solid sheet, pc corrugated sheet, pc sheet, pc roofing

OASIS polycarbonate corrugated sheets is available in a wide profile rangewhich includes all commonly used stadia, industrial, horticultural,agricultural, and DIY profile.Non-standard and bespoke profiles are available for a guaranteedminimum order, profiles can be matched to most corrugated metal roofingand cladding system

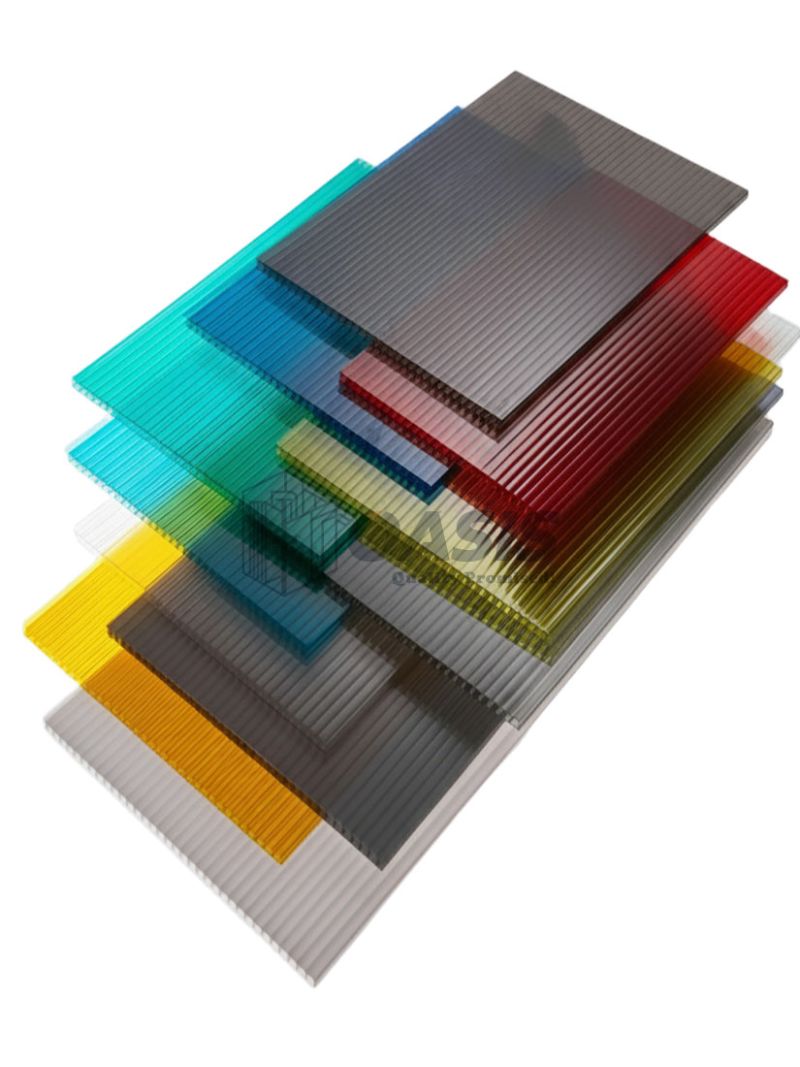

polycarbonate hollow sheet, polycarbonate sheet, pc hollow sheet, pc sheet, pc roofing, polycarbonate roofing

Unpacking the Benefits of Polycarbonate Hollow Sheets

pc roofing, polycarbonate roofing, pc roofing sheet, polycarbonate roofing sheet, pc hollow sheet

Car wash facilities present a unique and demanding environment for building materials. Constant exposure to water, chemicals, and fluctuating temperatures can quickly degrade conventional roofing. This is where polycarbonate roofing sheets shine, offering an ideal solution for car wash sites that prioritizes durability, natural lighting, and resistance to harsh conditions.

pc roofing, polycarbonate roofing, pc roofing sheet, polycarbonate roofing sheet, pc hollow sheet, facade, architecture

Once relegated primarily to greenhouses and simple industrial roofing, polycarbonate sheets have emerged as a powerhouse material in contemporary architecture.1 Architects now leverage its unique properties—transparency, extreme durability, and energy efficiency—to create dynamic, light-filled, and sustainable building facades, envelopes, and roofing systems that challenge the dominance of traditional glass

pc roofing, polycarbonate roofing, pc roofing sheet, polycarbonate roofing sheet, statium, Arena Roofing

Modern stadium and arena design demands roofing materials that provide expansive, all-weather coverage without sacrificing natural light, aesthetic appeal, or structural safety. Polycarbonate roofing sheets have become a foundational material for large-scale sports venues globally, replacing heavier materials like glass or opaque metals due to their combination of light weight, extreme durability, and optical versatility.

pc roofing, polycarbonate roofing, pc roofing sheet, polycarbonate roofing sheet, pc hollow sheet

Polycarbonate roofing sheets are the premier choice for covering walkways, canopies, and covered entrances, offering an ideal balance of transparency, durability, and UV protection. Unlike traditional opaque materials, polycarbonate provides shelter from the elements while maximizing the penetration of natural daylight, making covered areas bright, safe, and inviting.