Polycarbonate Hollow Sheets

The Smart Choice for Glazing and Roofing

Unpacking the Benefits of Polycarbonate Hollow Sheets

Polycarbonate hollow sheets, also widely known as multiwall or twin-wall polycarbonate, have emerged as a revolutionary material in the construction and architecture industries. Far surpassing the capabilities of traditional glass and acrylic in many applications, these fluted thermoplastic panels offer a unique combination of lightness, durability, and superior thermal performance.

From massive industrial greenhouses to residential pergolas and modern façade systems, polycarbonate hollow sheets provide an innovative, energy-efficient solution for letting light in while keeping the elements out.

What Makes Them "Hollow"? The Multiwall Design

The key to the sheets' exceptional performance lies in their structure. Unlike solid polycarbonate, which is a single, dense panel, hollow sheets consist of two or more parallel layers of polycarbonate held apart by vertical connecting ribs, creating internal air chambers.

- Twin-Wall (Bilayer): The most common variety, with two sheets separated by ribs.

- Triple-Wall, Four-Wall, and Honeycomb: Thicker versions with more internal layers and complex cell geometries, designed for maximum thermal insulation and rigidity.

This design mimics the insulating effect of double-pane glass, trapping air to create a highly effective thermal barrier.

Projects

Key Advantages for Modern Construction

The multiwall structure unlocks a host of benefits that make this material ideal for a wide range of projects:

1. Superior Thermal Insulation (Energy Efficiency)

The trapped air pockets within the fluted channels significantly reduce heat transfer. This is a crucial advantage for projects focused on energy efficiency.

- Heat Retention: In cold climates, the sheets help retain warmth, substantially lowering heating costs for spaces like greenhouses and sunrooms.

- Reduced Cooling Load: In hot climates, they prevent the interior temperature from rising heavily, reducing the need for air conditioning.

2. Unmatched Impact Strength

Polycarbonate is an extraordinarily tough plastic. When formed into a multiwall sheet, its impact resistance is legendary:

- Virtually Unbreakable: Polycarbonate sheets are up to 250 times stronger than traditional glass of the same thickness.This makes them highly resistant to hail, windborne debris, and vandalism.

- Safety: They are shatterproof, eliminating the danger of broken glass fragments and making them the material of choice for public shelters and industrial glazing.

3. Lightweight and Easy to Install

Despite their strength and volume, hollow sheets are incredibly light, often less than one-tenth the weight of glass.

- Lower Structural Costs: The reduced weight means lighter framing and support structures can be used, cutting overall construction material costs.

- DIY and Quick Installation: They are easy to handle, cut, and install with standard tools, speeding up construction time significantly.

4. High Light Transmission with UV Protection

Polycarbonate sheets can transmit a high degree of natural light—often up to 80% for clear varieties—while maintaining a crucial safeguard.

- UV Blocking: The outer surface is co-extruded with a specialized layer that blocks virtually all harmful UV radiation (98%).This prevents the sheet itself from yellowing and protects people, plants, and interiors beneath it from sun damage.

- Light Diffusion: The multiwall structure naturally diffuses light, reducing harsh glare and creating a softer, more uniform illumination, which is ideal for plant growth in greenhouses.

5. Design Flexibility

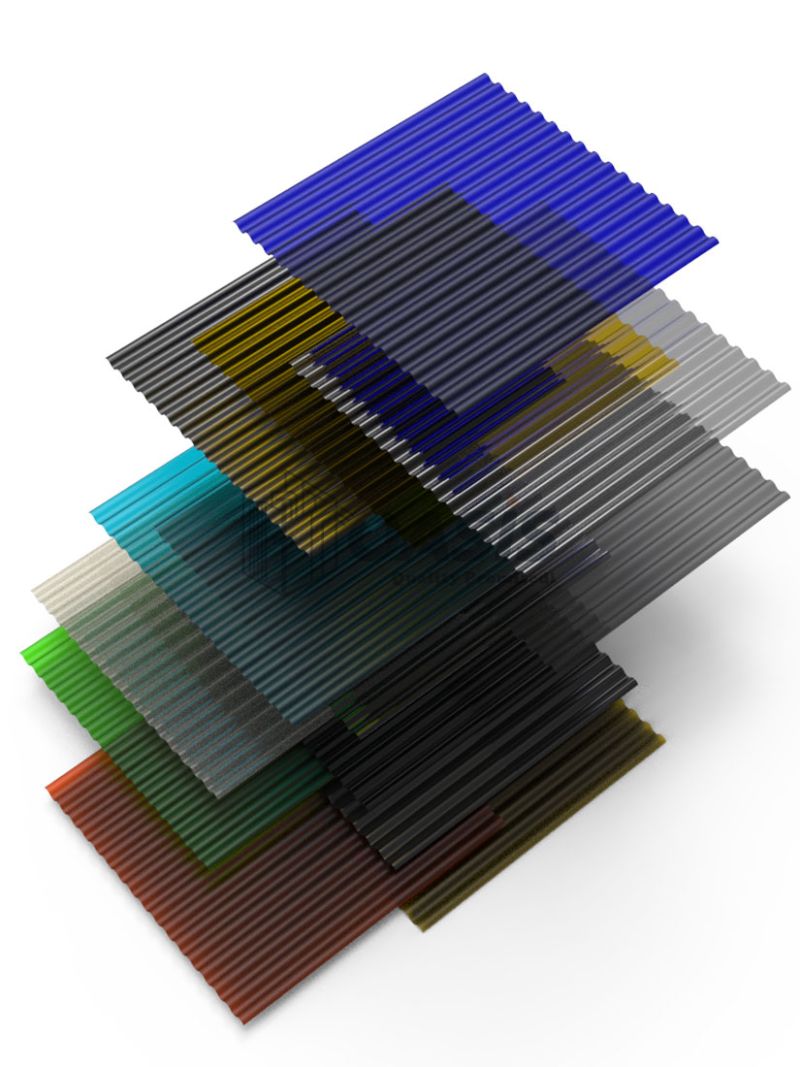

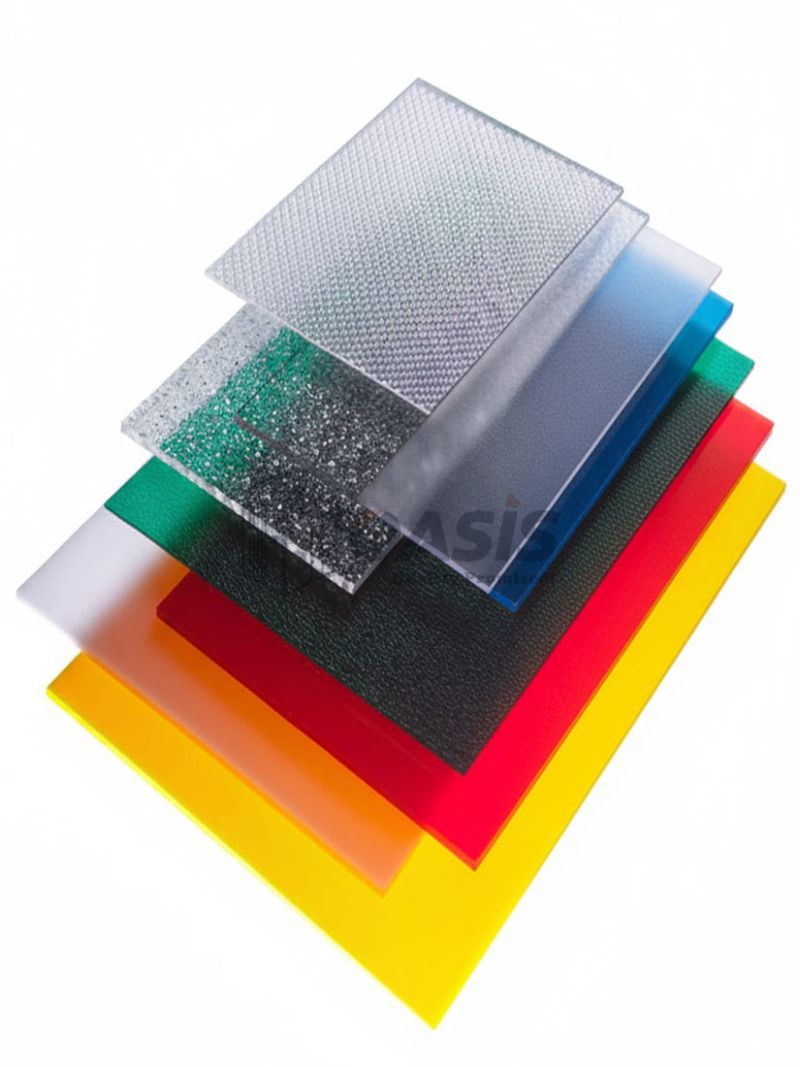

Polycarbonate sheets can be cold-formed or curved on-site, allowing architects and builders to create unique, non-flat designs that are difficult or impossible to achieve with glass. They are available in a variety of colors and tints (clear, bronze, opal) to control light and provide privacy.

Common Utilities

The versatility of multiwall polycarbonate is visible across commercial, residential, and agricultural sectors:

- Glazing & Roofing: Residential patios, pergolas, sunrooms, and carports.

- Agricultural Greenhouses: Providing optimal light and thermal conditions for crop cultivation.

- Commercial Skylights and Clerestories: Allowing natural light into warehouses and commercial buildings to save on lighting costs.

- Public Structures: Walkway canopies, bus shelters, and pool enclosures.

- Industrial: Sound barriers along highways and protective machine guards.

In summary, the polycarbonate hollow sheet is a triumph of material engineering, offering an ideal blend of insulation, durability, and optical clarity. As the world moves toward more sustainable and energy-efficient building practices, this versatile multiwall material is set to remain at the forefront of modern construction.

Advantage

- Energy saving

- Excellent impact resistance

- Lightweight

- High light transmission

- Weather and UV resistant benefits

- Superb thermal insulation - Energy saving

- Blocks virtually all UV radiation

- Easy to handle and install

- High fire performance rating

Application

- House / Shopping Mall Roofing

- Factory / Warehouse Roofing

- Gymnasiums Roofing

- Industrial Roofing and Glazing

- Indoor Partial

- Canopy / Carport

- Do-It-Yourself (DIY)

- Greenhouses

- Skylights

- Covered Walkways

Related Pages

polycarbonate corrugated sheet, polycarbonate solid sheet, pc corrugated sheet, pc sheet, pc roofing

OASIS polycarbonate corrugated sheets is available in a wide profile rangewhich includes all commonly used stadia, industrial, horticultural,agricultural, and DIY profile.Non-standard and bespoke profiles are available for a guaranteedminimum order, profiles can be matched to most corrugated metal roofingand cladding system

Polycarbonate solid sheet, polycarbonate roofing, polycarbonate sheet, pc solid sheet, pc sheet

The Clear Alternative to Glass

pc roofing, polycarbonate roofing, pc roofing sheet, polycarbonate roofing sheet, pc hollow sheet

Car wash facilities present a unique and demanding environment for building materials. Constant exposure to water, chemicals, and fluctuating temperatures can quickly degrade conventional roofing. This is where polycarbonate roofing sheets shine, offering an ideal solution for car wash sites that prioritizes durability, natural lighting, and resistance to harsh conditions.

pc roofing, polycarbonate roofing, pc roofing sheet, polycarbonate roofing sheet, pc hollow sheet, facade, architecture

Once relegated primarily to greenhouses and simple industrial roofing, polycarbonate sheets have emerged as a powerhouse material in contemporary architecture.1 Architects now leverage its unique properties—transparency, extreme durability, and energy efficiency—to create dynamic, light-filled, and sustainable building facades, envelopes, and roofing systems that challenge the dominance of traditional glass

pc roofing, polycarbonate roofing, pc roofing sheet, polycarbonate roofing sheet, statium, Arena Roofing

Modern stadium and arena design demands roofing materials that provide expansive, all-weather coverage without sacrificing natural light, aesthetic appeal, or structural safety. Polycarbonate roofing sheets have become a foundational material for large-scale sports venues globally, replacing heavier materials like glass or opaque metals due to their combination of light weight, extreme durability, and optical versatility.

pc roofing, polycarbonate roofing, pc roofing sheet, polycarbonate roofing sheet, pc hollow sheet

Polycarbonate roofing sheets are the premier choice for covering walkways, canopies, and covered entrances, offering an ideal balance of transparency, durability, and UV protection. Unlike traditional opaque materials, polycarbonate provides shelter from the elements while maximizing the penetration of natural daylight, making covered areas bright, safe, and inviting.