Mirror Polyestyrene Sheets

Polystyrene mirror sheet, also known as styrene mirror, is a lightweight,

reflective plastic material that serves as a low-cost, shatter-resistant

alternative to traditional glass mirrors. It is made from a sheet of

high-impact polystyrene (HIPS) laminated with a thin,

metallized polyester film that provides the reflective surface.

It's primarily intended for indoor use.

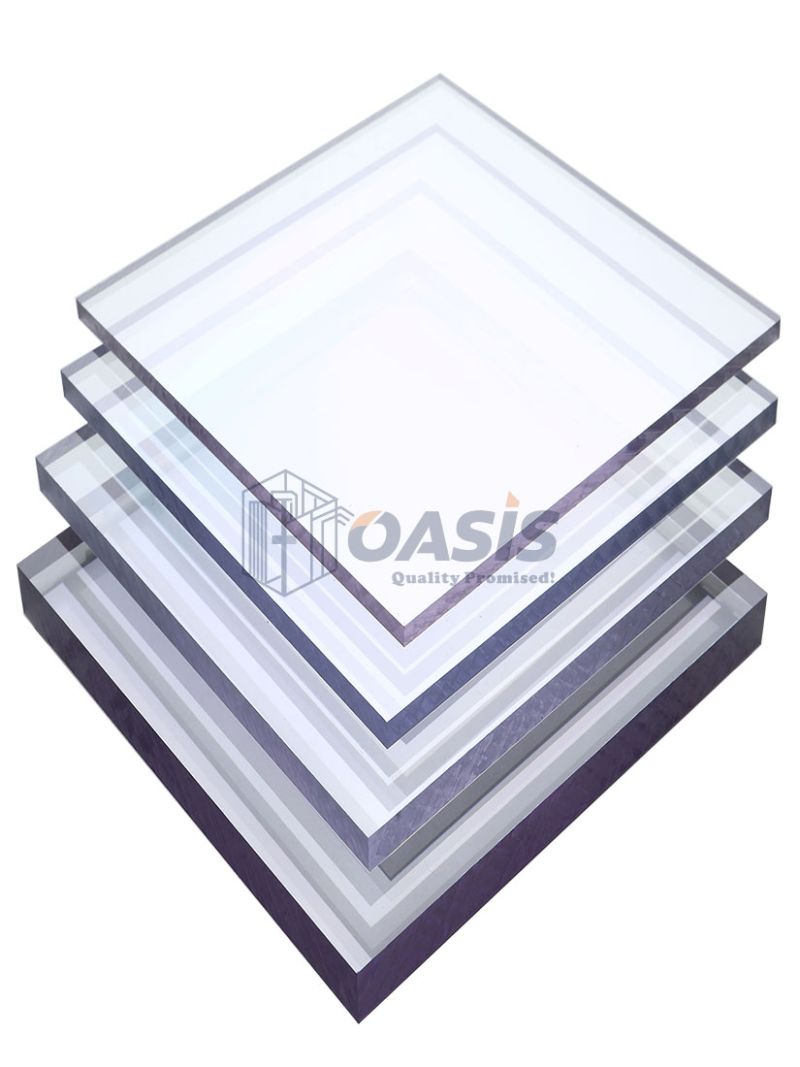

SPECIFICATION

| Popular Thickness | 2.0mm, 3.0mm |

| Popular size(mm) | 1220×2440mm; 1220×1830mm; |

| Color | Silver, Golden, Pink, Red, Purple |

| Density | 1.05Kg/m³ |

| Package | Kraft paper or Pallet |

| Material | 100% virgin polystyrene resin |

Color Picker

Manufacture

Stock

Projects

Key Properties & Characteristics

Lightweight: Polystyrene mirror sheets are significantly lighter than glass mirrors of the same size, making them easier to handle, transport, and install.

Shatter-Resistant: Unlike glass, this material won't shatter into sharp, dangerous shards upon impact, making it a safer option for applications in public spaces, children's areas, and high-traffic environments.

Cost-Effective: It's generally more affordable than both glass and other plastic mirror alternatives like acrylic or polycarbonate.

Ease of Fabrication: It can be easily cut, drilled, and fabricated using standard tools, which makes it popular for DIY projects, signage, and decorative applications.

Common Uses & Applications 🛠️

Polystyrene mirror sheets are a popular choice for a variety of applications where safety, weight, and cost are key considerations. They're often used for:

Point-of-Sale (POP) Displays and Signage: Their reflective quality and ease of use make them ideal for creating eye-catching displays and signs in retail environments.

Decorative Purposes: They're used for interior design, crafts, and architectural models, adding a reflective element to various projects.

Security and Surveillance: They can be used as a simple and cost-effective reflective surface in security applications.

Toys and Novelty Items: Due to their shatter-resistant nature, they're safe for use in children's toys.

DIY Projects: The material is easy to work with, making it a favorite for home improvement and craft projects.

Polystyrene vs. Acrylic Mirror Sheet ⚖️

While both are popular plastic mirror options, there are key differences to consider:

Durability and Impact Strength: Acrylic mirror is significantly stronger and more impact-resistant than polystyrene mirror. Polystyrene mirror can still crack or break upon impact, although it is safer than glass.

Optical Clarity: Acrylic mirrors generally offer a clearer, more glass-like reflection with less distortion. Polystyrene mirrors tend to have a less brilliant and potentially more distorted reflection, especially on uneven surfaces.

Cost: Polystyrene mirror is typically the cheaper of the two.

Applications: Due to its superior impact resistance and clarity, acrylic mirror is often preferred for more demanding applications like dance studios, gyms, and safety mirrors in schools. Polystyrene is often sufficient for less critical decorative and display uses.

Related Pages

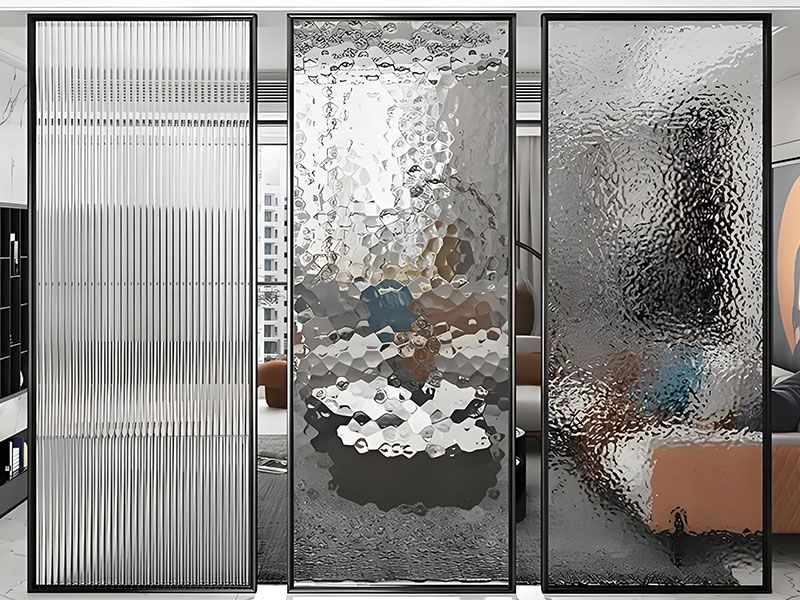

Polystyrene textured sheet usually refers to flat or corrugated sheets made from polystyrene (PS) plastic, manufactured with an embossed or patterned surface. These sheets are widely used in construction, decoration, packaging, and crafts because they are lightweight, easy to cut, and can be made in various textures and colors.

Extruded PS Sheet, Polystyrene\nSheet\nGPPS sheet also called PS sheet, Polystyrene Sheet has high clarity,\neasy to process, light\nweight, good light transmission, low humidity\nabsorbs rate, low cost, and high hardness characteristics. therefore this\nmaterial has widely used on shower doors, indoor partition, UV printing, Light box, advertising board, display shelf, household\ndecoration, package, crafts and advertising signs, architectural notice board,\ninstead of glass, picture frame etc. also this material is cost-effective\ncompared to acrylic material. We provide 4 types of GPPS sheets: flat, pattern,\nmirror and UV printing.

In modern office design, flexibility, aesthetics, and functionality are paramount. As businesses seek to create dynamic, adaptable, and visually appealing workspaces, polystyrene embossed sheets are emerging as an innovative material for partition walls. By offering a unique combination of light diffusion, decorative texture, and practical benefits, these sheets can transform standard office dividers into stylish, efficient, and semi-private architectural elements.

For homeowners and designers seeking a unique, durable, and moisture-resistant solution for bathroom doors, polystyrene embossed sheets offer an innovative alternative to traditional materials. By combining the inherent advantages of polystyrene with decorative textures, these sheets can transform a utilitarian fixture into a stylish design element, perfectly suited for the challenging bathroom environment.

In the high-energy, high-traffic environment of a modern fitness center, doors must meet a demanding list of requirements: they need to withstand constant use, resist moisture from sweat and shower areas, be easy to clean, and contribute to the facility's motivating aesthetic. Polystyrene embossed sheets offer a practical, stylish, and highly durable solution for doors within a gym setting.

Polystyrene frosted sheets have become a prevalent and cost-effective material in the signage and display industries, particularly as the face of LED light boxes. These sheets offer the critical balance of excellent light diffusion, durability, and cost-efficiency required to produce brightly, uniformly lit graphics for retail, advertising, and corporate branding.